Hot Rolled Stainless Steel Coil Manufacturer

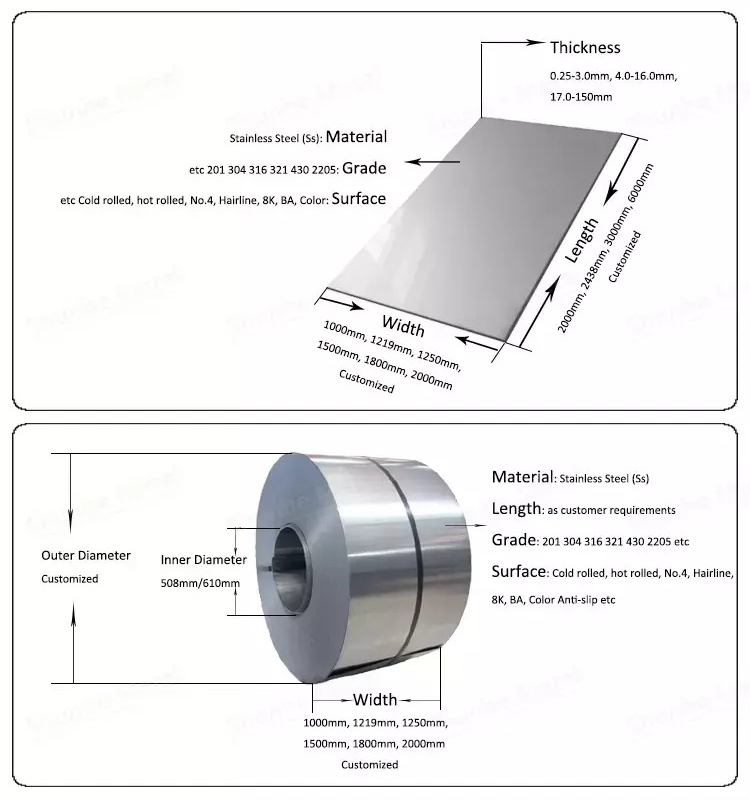

Hot-rolled stainless steel coil is also called stainless steel crude steel. Hot-rolled stainless steel coil is made of stainless steel continuous casting slab or blooming slab as raw material. The rolling mill and the finishing mill, after the final rolling, are cooled by laminar flow and coiled by a coiler to become a hot-rolled black skin coil. After pickling to remove the oxide skin, it is a hot-rolled stainless steel coil. Most of the hot-rolled stainless steel is used as the raw material for the production of cold-rolled stainless steel, and a small amount is directly used as an industrial material for the manufacture of corrosion-resistant parts, containers and equipment in the chemical, petroleum, machinery, shipbuilding and other industries.

Inquire Now