Production Process of Stainless Steel Mirror Plate/Sheet

1.Melting

The elements of the stainless steel are first melted down together in a furnace for 8-12 hours. Often, scrap metal and recycled stainless steel is used for this process. The temperature at which the metal is melted will vary based on the grade of steel being made.

2.Carbon Removal

After the mixture is melted, extra carbon content must be removed. While carbon is an essential part of stainless steel, too much can create issues. Carbon can be removed in one of two ways: either through processing in an argon oxygen decarburization (AOD) converter, or through vacuum oxygen decarburization (VOD). When using an AOD, an oxygen-carbon mixture is injected into the molten metal, which removes the extra carbon. With VOD, oxygen is injected into the metal in a chamber, and the released carbon gas is vacuumed out.

3.Tuning

After carbon removal, the metal mixture is fine-tuned to ensure that it meets the standard requirements of its grade. This involves the removal of excess elements and the balancing of the chemicals in the metal.

4.Casting and Forming

Next, the mixture is cast or formed into its shape. Some typical forms include blooms, billets, slabs, rods, and tubes. From here, the steel will be crafted into its final form.

5.Hot Rolling

Hot rolling is done at the temperature above the recrystallization temperature of the stainless steel. In this process, the metal is rolled, and the approximate form given at casting is made into a more precise form.

6.Cold Rolling

Cold rolling occurs just below the recrystallization temperature of the metal. This process uses multiple rollers and gives the metal an even more precise shape and a nice finish.

7.Annealing

During the annealing process, the metal is repeatedly heated and cooled. This helps to soften the steel and improve certain qualities like ductility.

8.Descaling

By this point in the manufacturing process, scale has generally formed on the steel. Scale can be detrimental to the steel and must be removed. This is achieved either by heating and cooling the metal further in an environment without oxygen, or by covering the metal in an acid mixture.

9.Cutting

After all these steps are completed, the steel can finally be cut. There are several methods that can be used to cut stainless steel. It can be cut mechanically with guillotine knives, circular knives, high-speed blades, or by using metal punches and dies. It can also be cut using flame cutting or plasma jet cutting, which use a torch or ionized gas and an electric arc, respectively.

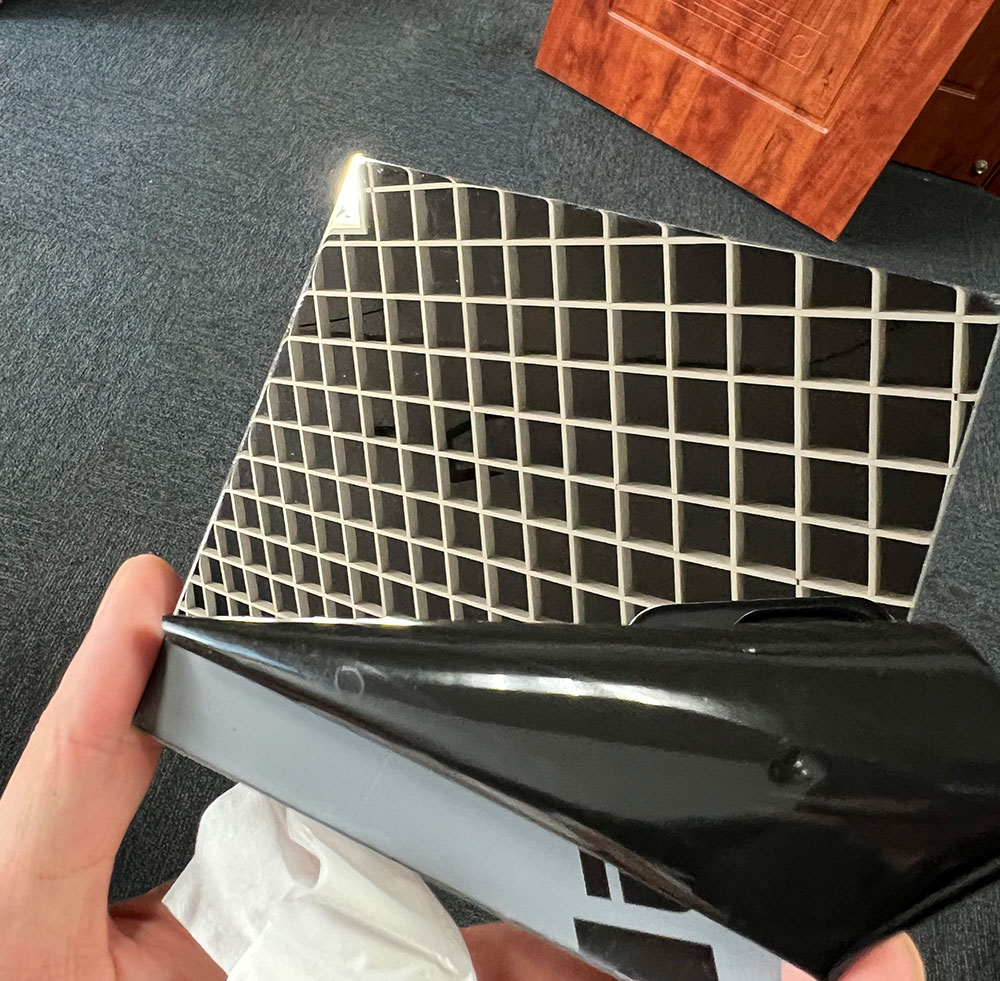

10.Finishing

The final stage of stainless steel manufacturing is the finishing. Stainless steel comes in a variety of finishes achieved by different finishing methods. Among these are sand blasting, wet etching with acid, buffing, and polishing.A polished mirror finish is created by rubbing the metal with gradually finer abrasives. Before the polishing process begins, any defects on the surface of the metal, including scratches, must be removed. This process is called pre-grinding. Finally, the surface of the metal is buffed for 5-10 minutes to make the metal bright, smooth, and mirror-like. Though both brushed and mirror finishes are polished, the mirror finish is even more resistant to corrosion than the brushed finish, since it is completely smooth and has no grooves. The mirror finish is typically used decoratively or for materials that must be reflective, like mirrors.